SPINNAKER JIBES ON SALIENT

This document is adapted from a procedure developed and successfully used on String Theory in two Vic-Maui races and in various training races. It has subsequently been adapted to support inshore round the buoys racing as well. The purpose of this document is to provide a standard technique for jibing the symmetrical spinnakers on Salient keeping in mind the way the boat is rigged, safety and the conditions in which we will be sailing.

Before beginning to practice the steps below, we must mark the topping lift, both guys and both sheets. These marks will help us to accurately and quickly move the respective lines to their correct positions during a jibe, day or night. The pole car at the mast has already been marked with a white tape line.

• Mark topping lift so that the pit person can tell when the topping lift has been eased enough to pass through the fore-triangle with the pole car at the black band on the mast.

• Mark both guys and both sheets so that the trimmers can tell when a sheet or guy has been hardened sufficiently to bring the pole back nearly square.

The basic idea will be to control the spinnaker with its two sheets only while:

• The boat turns beneath the spinnaker and the spinnaker's orientation with respect to the rest of the world outside the boat remains constant. They key is to keep the spinnaker downwind of the boat.

• The main trimmer jibes the mainsail in a controlled manner.

• The old guy is tripped away from the pole, the pole is swung forward to the bowman, the bowman clips the new guy into the pole's jaws and the pole is brought back on the new jibe.

The entire jibe should take about 10 seconds. The spinnaker should remain full during the entire jibe.

Before beginning to practice the steps below, we must mark the topping lift, both guys and both sheets. These marks will help us to accurately and quickly move the respective lines to their correct positions during a jibe, day or night. The pole car at the mast has already been marked with a white tape line.

• Mark topping lift so that the pit person can tell when the topping lift has been eased enough to pass through the fore-triangle with the pole car at the black band on the mast.

• Mark both guys and both sheets so that the trimmers can tell when a sheet or guy has been hardened sufficiently to bring the pole back nearly square.

The basic idea will be to control the spinnaker with its two sheets only while:

• The boat turns beneath the spinnaker and the spinnaker's orientation with respect to the rest of the world outside the boat remains constant. They key is to keep the spinnaker downwind of the boat.

• The main trimmer jibes the mainsail in a controlled manner.

• The old guy is tripped away from the pole, the pole is swung forward to the bowman, the bowman clips the new guy into the pole's jaws and the pole is brought back on the new jibe.

The entire jibe should take about 10 seconds. The spinnaker should remain full during the entire jibe.

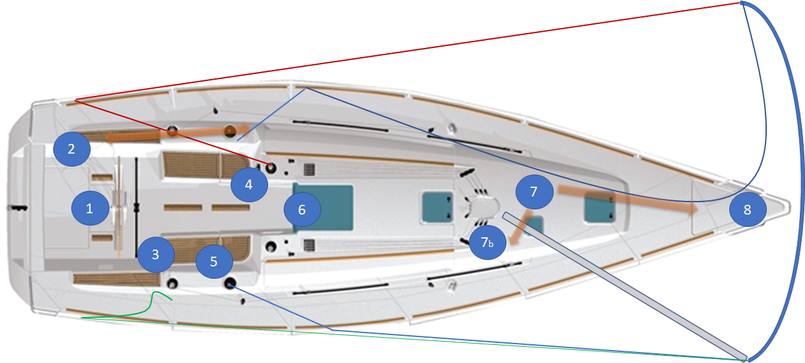

Stage 1 - Set-up

| Step | 1-Helm | 2-Floater | 3-Main | 4-Port Trim | 5-STBD Trim | 6-Pit | 7-Mast | 8-Bow |

|---|---|---|---|---|---|---|---|---|

| 0 | Calls for jibe | relays call for jibe to foredeck | ||||||

| 1 | Keeps the boat going fast, on course | Trims main using stbd. aft winch | Trims spin sheet using port aft winch | Controls guy using stbd. fwd. winch | Makes sure all lines are tidy and free to run | Makes sure pole is level for best trim | Makes sure lazy sheet is over end of pole and bow clear for jibe | |

| 2 | Makes sure lazy guy is free to go fwd and loads guy on fwd port winch | Takes lazy guy fwd to Bow | Takes lazy Guy to pulpit and sets-up for jibe | |||||

| 3 | ready | ready | ready | Ready | ready | ready | ready | ready |

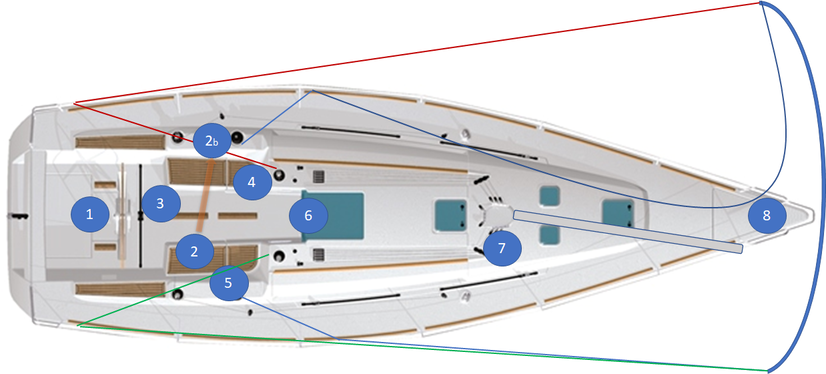

Stage 2 - Entering the jibe

| Step | 1-Helm | 2-Floater | 3-Main | 4-Port Trim | 5-STBD Trim | 6-Pit | 7-Mast | 8-Bow |

|---|---|---|---|---|---|---|---|---|

| 4 | Calls "Square Back" and starts to bear away | loads stbd. spin sheet on cabin top winch | centers traveler | Communicates with STBD trimmer and trims spin. as boat heads downwind | squares pole back and prepares to take stbd sheet when pole tripped. | relays "Square Back", eases the downhaul as pole is squared back | ||

| 5 | Calls "Trip" when far enough downwind | takes STBD guy from STBD trimmer | locks Stb main clutch. Clears main sheet off stbd. aft winch and loads port aft winch | responsible for calling trim of spinnaker and keeps Spin downwind of the boat | Takes up tension on STBD sheet and works with Port trimmer to trim spinnaker. | Trips the pole then raises mast end of pole to mast mark | ||

| 6 | Steers smoothly through jibe. | once STBD guy is off the pole and STBD sheet has control of the sail moves over to Port guy to be ready to take up tension | Centers main and eases vang if needed. | responsible for calling trim of spinnaker and keeps Spin downwind of the boat | works with Port trimmer to trim spinnaker. | lowers topping lift to mark after Mast Trips the Pole | Pushes pole forward to bow | watches for pole to come to him. Calls for assistance from Mast if needed. |

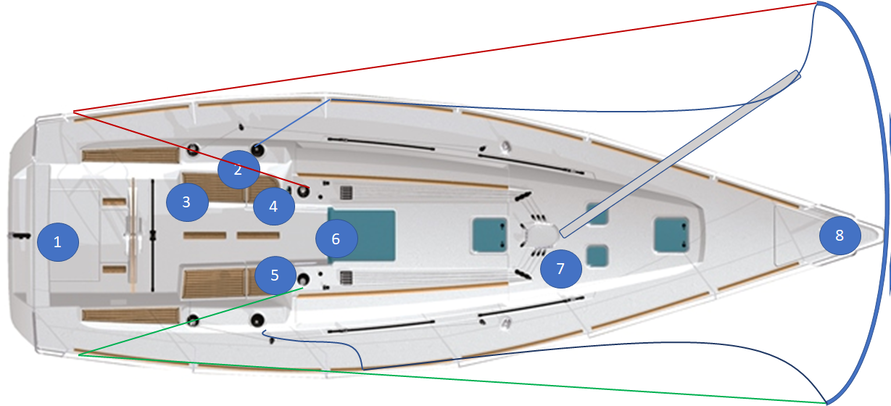

Step 3 - finish the jibe

| Step | 1-Helm | 2-Floater | 3-Main | 4-Port Trimmer | 5-STBD Trimmer | 6-Pit | 7-Mast | 8-Bow |

|---|---|---|---|---|---|---|---|---|

| 7 | Steers smoothly through jibe. | Watches the Bow for the call "Made" and prepares to harden port guy. | Switches to port aft winch | Responsible for calling trim of spinnaker and keeps Spin downwind of the boat | works with Port trimmer to trim spinnaker. | relays any messages required to and from the Bow | Helps the old guy clear the pole jaw if need be, then helps the pole tip swig inboard to the bow | Clips the new guy into the pole jaw and pushes the pole to port, making sure the sheet is on top of the pole |

| 8 | Calls “Made” | |||||||

| 9 | Hardens new guy on port winch | Jibes the main and lets the sheet out on the new jibe | works with STBD trimmer to trim spinnaker. | takes over responsibility for calling trim of spinnaker and keeps Spin downwind of the boat | Hardens the topping lift to pre-jibe position | As soon as the pole is through the foretriangle and clear of lifelines and sail, bring the pole car down to the pre-jibe position |

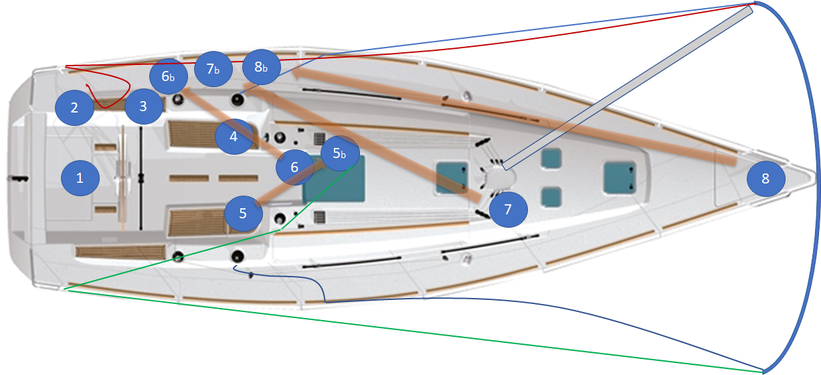

Step 4 - up to Speed

| Step | 1-Helm | 2-Floater | 3-Main | 4-Port Trimmer | 5-STBD Trimmer | 6-Pit | 7-Mast | 8-Bow |

|---|---|---|---|---|---|---|---|---|

| 10 | Holds boat on broad reach | Trims guy for coarse | Trims Main on Port Aft winch | cleans up Port spinnaker sheet | Trims Spinnaker and calls for pole set | Trims pole height to trimmers requests | Makes sure pole is level for best trim | Clears Bow |

| 11 | Heads up to proper coarse | Hands off to port trimmer | Trims main in coordination with how the helm feels | Trims guy to final coarse | Trims spinnaker | Cleans up lines and ensures pole height can be adjusted easily | Cleans up lines and works with Bowman to make sure port Sheet is over end of pole | Ensures port sheet is over the end of the pole and bow is clear for next manouver |

| 12 | Smiles and says "Great Jibe!". Keeps the boat going fast, on course | Moves back to propoer position for boat trim | Trims main using port aft winch | Trims spin sheet using stbd. cabin top winch | keeps weight balanced and helps port trim with griding as needed | Moves to position for boat trim | Moves to position for boat trim | Moves to position for boat trim |